English ![]()

T: +86-18156545248

E: info@wnksensor.com

E: info@wnksensor.com

5F, Bldg. 2A, Mingzhu Industrial Park Hefei 230000, China

WNK5S pressure transmitters are suitable for:

1.Gauge,absolute and differential pressure measurement in gases,steam or liquids in areas of process control field.| Availability: | |

|---|---|

| Quantity: | |

WNK55

WNK

Applicable media | liquid, gas and steam |

Pressure range | -100KPa~6MPa |

Accuracy | 0.075%, higher on request |

Stability | ±0.25% of URL for 1 year |

Temperature drift | ±0.0625% of URL/10ºC |

Output signals | 4~20mA, Hart, PROFIBUS-PA for option |

Housing material | Aluminum14 |

Mechanical connection | M20×1.5;G1/2;1/2NPT |

Protection class | IP66/67 |

Diaphragm material | 316L, Alloy C-276, Monel, Tantalum diaphragm, 316L with PTFE coating etc for option |

Fluid filled | Silicon oil,Vegetable oil,Inert oil ,High temperature oil etc for option |

Ex-proof | Exia II CT4, other option per request |

Power Supply | 10.5-55V DC 10.5-30V DC |

Ambient temperature | -40 to 85ºC,-40 to 80ºCfor LCD header |

Storage temperature | -45 to 85ºC,-40 to 80ºC for LCD header |

Features | Applications: |

1. High reference accuracy up to 0.075%, higher on request. | Gauge & absolute pressure measurement in gases, steam or liquids in all areas of of engineering process and measurement. |

2. Long-term drift ≤±0.25%URL for 1 year. | |

3. Range down ratio 100:1; higher on request. | Level measurement in liquids. |

4. Replaceable display unit & electronic module. | High process temperatures up to 280ºC with diaphragm seals. |

5. Universal electronics. | It can be used below particular occasiaon |

6. Menu-guided operation. | 1. Need to isolate the high temperature medium with transmitter |

7. Factory default data recovery is supportive | 2. The measuring medium is corrosive to the transmitter |

8. Hart, PROFIBUS-PA or FF protocol for option. | 3. The measuring medium solidification or crystallization due to environmental or temperature changes |

4. Suspended liquid or high viscosity medium |

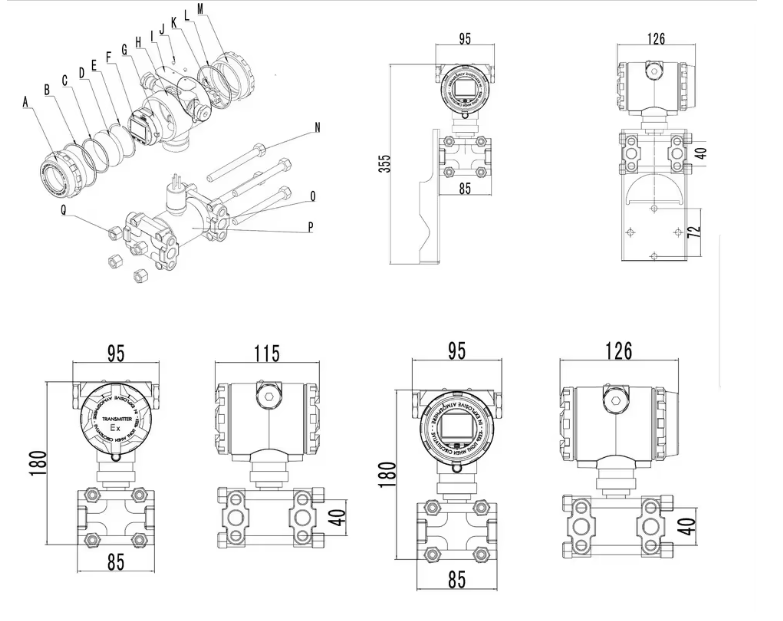

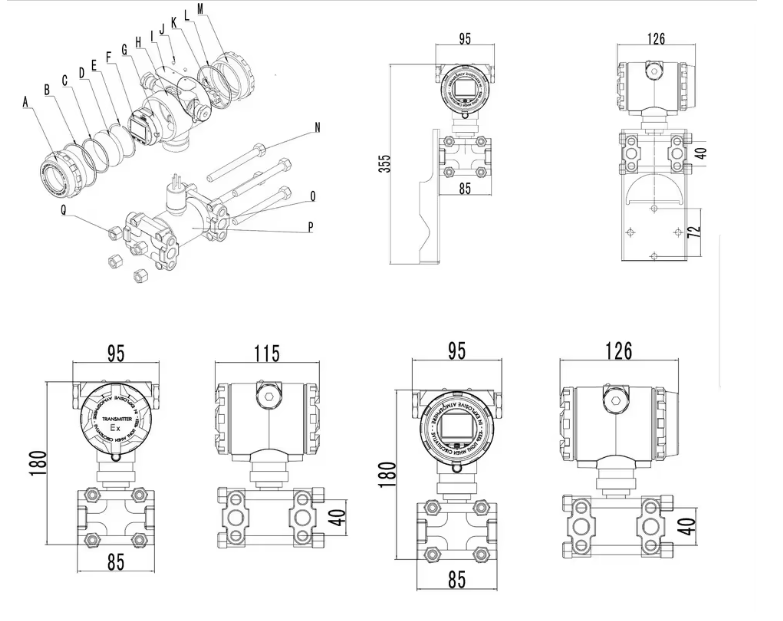

The WNK55 4-20mA Smart Explosion Proof Differential Transmitter is a high-performance instrument designed for precise pressure measurement in diverse industrial environments. Manufactured by WNK, a leading provider of pressure sensing solutions, this transmitter excels in measuring gauge, absolute, and differential pressure in gases, steam, and liquids. It is engineered to meet the demands of process control, level monitoring, and critical industrial applications where accuracy, reliability, and safety are paramount.

Equipped with advanced features such as explosion-proof certification, flexible output signals, and robust construction, the WNK55 is suitable for harsh conditions, including corrosive media, high temperatures, and hazardous areas. Its universal design ensures compatibility with various systems, making it a versatile choice for industries ranging from chemical processing to HVAC and oil & gas.

Parameter | Details |

Applicable media | liquid, gas and steam |

Pressure range | -100KPa~6MPa |

Accuracy | 0.075%, higher on request |

Stability | ±0.25% of URL for 1 year |

Temperature drift | ±0.0625% of URL/10ºC |

Output signals | 4~20mA, Hart, PROFIBUS-PA for option |

Housing material | Aluminum14 |

Mechanical connection | M20×1.5; G1/2; 1/2NPT |

Protection class | IP66/67 |

Diaphragm material | 316L, Alloy C-276, Monel, Tantalum diaphragm, 316L with PTFE coating (options) |

Fluid filled | Silicon oil, Vegetable oil, Inert oil, High temperature oil (options) |

Ex-proof | Exia II CT4, other options per request |

Power Supply | 10.5-55V DC; 10.5-30V DC |

Ambient temperature | -40 to 85ºC; -40 to 80ºC for LCD header |

Storage temperature | -45 to 85ºC; -40 to 80ºC for LCD header |

The WNK55 transmitter stands out with a range of technical advantages that enhance its performance and usability:

· High reference accuracy up to 0.075%, with the option for even higher precision to meet stringent measurement requirements.

· Exceptional long-term stability, with a drift of ≤±0.25% URL over one year, ensuring consistent results without frequent recalibration.

· A wide range down ratio of 100:1 (higher available on request), allowing flexible measurement across varying pressure ranges.

· Replaceable display unit and electronic module, simplifying maintenance and reducing downtime.

· Universal electronics that adapt to different system configurations, enhancing compatibility.

· Intuitive menu-guided operation, making setup and adjustment user-friendly for operators of all skill levels.

· Factory default data recovery support, providing a safety net for accidental configuration errors.

· Optional communication protocols including Hart, PROFIBUS-PA, or FF, enabling seamless integration with industrial control systems.

The WNK55 4-20mA Smart Explosion Proof Differential Transmitter is widely used in:

· Gauge and absolute pressure measurement in gases, steam, or liquids across all areas of engineering process and measurement.

· Level measurement in liquids, ensuring accurate monitoring of fluid levels in tanks and vessels.

· High process temperatures up to 280ºC when paired with diaphragm seals, making it suitable for extreme heat environments.

· Specialized scenarios such as:

· Isolating high-temperature media from the transmitter to prevent damage.

· Handling measuring media that is corrosive to standard transmitters, thanks to optional diaphragm materials.

· Managing media prone to solidification or crystallization due to environmental or temperature changes.

· Measuring suspended liquids or high-viscosity media, where traditional sensors may fail.

Applicable media | liquid, gas and steam |

Pressure range | -100KPa~6MPa |

Accuracy | 0.075%, higher on request |

Stability | ±0.25% of URL for 1 year |

Temperature drift | ±0.0625% of URL/10ºC |

Output signals | 4~20mA, Hart, PROFIBUS-PA for option |

Housing material | Aluminum14 |

Mechanical connection | M20×1.5;G1/2;1/2NPT |

Protection class | IP66/67 |

Diaphragm material | 316L, Alloy C-276, Monel, Tantalum diaphragm, 316L with PTFE coating etc for option |

Fluid filled | Silicon oil,Vegetable oil,Inert oil ,High temperature oil etc for option |

Ex-proof | Exia II CT4, other option per request |

Power Supply | 10.5-55V DC 10.5-30V DC |

Ambient temperature | -40 to 85ºC,-40 to 80ºCfor LCD header |

Storage temperature | -45 to 85ºC,-40 to 80ºC for LCD header |

Features | Applications: |

1. High reference accuracy up to 0.075%, higher on request. | Gauge & absolute pressure measurement in gases, steam or liquids in all areas of of engineering process and measurement. |

2. Long-term drift ≤±0.25%URL for 1 year. | |

3. Range down ratio 100:1; higher on request. | Level measurement in liquids. |

4. Replaceable display unit & electronic module. | High process temperatures up to 280ºC with diaphragm seals. |

5. Universal electronics. | It can be used below particular occasiaon |

6. Menu-guided operation. | 1. Need to isolate the high temperature medium with transmitter |

7. Factory default data recovery is supportive | 2. The measuring medium is corrosive to the transmitter |

8. Hart, PROFIBUS-PA or FF protocol for option. | 3. The measuring medium solidification or crystallization due to environmental or temperature changes |

4. Suspended liquid or high viscosity medium |

The WNK55 4-20mA Smart Explosion Proof Differential Transmitter is a high-performance instrument designed for precise pressure measurement in diverse industrial environments. Manufactured by WNK, a leading provider of pressure sensing solutions, this transmitter excels in measuring gauge, absolute, and differential pressure in gases, steam, and liquids. It is engineered to meet the demands of process control, level monitoring, and critical industrial applications where accuracy, reliability, and safety are paramount.

Equipped with advanced features such as explosion-proof certification, flexible output signals, and robust construction, the WNK55 is suitable for harsh conditions, including corrosive media, high temperatures, and hazardous areas. Its universal design ensures compatibility with various systems, making it a versatile choice for industries ranging from chemical processing to HVAC and oil & gas.

Parameter | Details |

Applicable media | liquid, gas and steam |

Pressure range | -100KPa~6MPa |

Accuracy | 0.075%, higher on request |

Stability | ±0.25% of URL for 1 year |

Temperature drift | ±0.0625% of URL/10ºC |

Output signals | 4~20mA, Hart, PROFIBUS-PA for option |

Housing material | Aluminum14 |

Mechanical connection | M20×1.5; G1/2; 1/2NPT |

Protection class | IP66/67 |

Diaphragm material | 316L, Alloy C-276, Monel, Tantalum diaphragm, 316L with PTFE coating (options) |

Fluid filled | Silicon oil, Vegetable oil, Inert oil, High temperature oil (options) |

Ex-proof | Exia II CT4, other options per request |

Power Supply | 10.5-55V DC; 10.5-30V DC |

Ambient temperature | -40 to 85ºC; -40 to 80ºC for LCD header |

Storage temperature | -45 to 85ºC; -40 to 80ºC for LCD header |

The WNK55 transmitter stands out with a range of technical advantages that enhance its performance and usability:

· High reference accuracy up to 0.075%, with the option for even higher precision to meet stringent measurement requirements.

· Exceptional long-term stability, with a drift of ≤±0.25% URL over one year, ensuring consistent results without frequent recalibration.

· A wide range down ratio of 100:1 (higher available on request), allowing flexible measurement across varying pressure ranges.

· Replaceable display unit and electronic module, simplifying maintenance and reducing downtime.

· Universal electronics that adapt to different system configurations, enhancing compatibility.

· Intuitive menu-guided operation, making setup and adjustment user-friendly for operators of all skill levels.

· Factory default data recovery support, providing a safety net for accidental configuration errors.

· Optional communication protocols including Hart, PROFIBUS-PA, or FF, enabling seamless integration with industrial control systems.

The WNK55 4-20mA Smart Explosion Proof Differential Transmitter is widely used in:

· Gauge and absolute pressure measurement in gases, steam, or liquids across all areas of engineering process and measurement.

· Level measurement in liquids, ensuring accurate monitoring of fluid levels in tanks and vessels.

· High process temperatures up to 280ºC when paired with diaphragm seals, making it suitable for extreme heat environments.

· Specialized scenarios such as:

· Isolating high-temperature media from the transmitter to prevent damage.

· Handling measuring media that is corrosive to standard transmitters, thanks to optional diaphragm materials.

· Managing media prone to solidification or crystallization due to environmental or temperature changes.

· Measuring suspended liquids or high-viscosity media, where traditional sensors may fail.

WNK5S pressure transmitters are suitable for:

1.Gauge,absolute and differential pressure measurement in gases,steam or liquids in areas of process control field.Ready to ship,Mini brass pressure sensor low cost unit price $6 USD.

WNK85MA is a series of high performance compact pressure transmitter by using ASIC signal conditioning chip and dry ceramic capacitive pressure sensor. It has features of anti-corrosion, anti-wear, shock resistance and vibration resistance. Its anti-overload capacity is over 3-5 times of the range, completely solved poor overload in small range of other sensors. In addition to general ranges of normal sensors, its most outstanding characteristic is the positive and negative gauge pressure function. As high output and wide range of its core ceramic capacitive sensor, WNK85MA is especially suitable for harsh industrial environment pressure measurement.

WNK811 is a series of high performance compact pressure transducer, by using ASIC signal conditioning chip and dry ceramic capacitive pressure sensor. It has features of anti-corrosion, anti-wear, shock resistance and vibration resistance. Its anti-overload capacity is up to 10 times of the range, completely solved poor overload in small range of other sensors. In addtion to general ranges of normal sensors, its most outstanding characteristic is the positive and negative gauge pressure function. With high output and wide range, WNK80MA is especially suitable for manufacturing of high-performance industrial control pressure transmitter and harsh environment pressure measurement.

The WNK125P is a diffusible silicon oil-filled pressure sensor designed forautomotive use. The element is made with a fully welded 316L diaphragm anddoes not require any O-ring seals that could come into contact with the pressuremedium, making it compatible with all types of liquids. The absence of anymoving parts results in a longer service life. With high temperature stability andaccuracy,this pressure sensor is mainly used in automotive, transmission, airconditioning and oil pressure measurement applications.